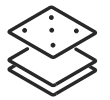

PREMIUM FOAMS // In all our premium mattresses, we use a high density foam to maintain a long-lasting comfort.

QUALITY BOX SPRINGS // Featuring heavy duty True-Flex springs.

CENTER SUPPORT // Featuring Ring Flex in our mattress centers. While all mattresses will eventually show some body impression, this feature helps alleviate this problem.

FULL EDGE SUPPORT // We use Edge Guard technology for full edge support to eliminate broken edges and border wire.

VISCO FOAM // Visco is a memory foam developed by NASA. Visco is sensitive to body heat. Hence the warmer it becomes, the softer it will be. Visco tends to sleep warmer. Heartland uses a brand using cool technology that sleeps 2° cooler than other memory foams. All our Visco beds feature a 4 lb. or better quality.

LATEX FOAM // Latex foam is a natural foam using sap from a rubber tree which is boiled down and poured into a form with pins, forming air holes, allowing it to breathe. Latex is a premium foam with a projected lifetime of 20-25 years. Latex is also a natural dust mite deterrent, so you will have less dust in your mattresses, hence better quality of air at night and less prone to allergies. Because all-natural Latex is extremely heavy and expensive, we used a blended version.

SERENE® // Specialty foam that self-adjusts to individual body contours.

POCKETED COILS // Our pocketed coil units feature individual coils, wrapped in fabric. This allows the coils to flex and conform to the individual contours of the body. This coil design is very unique and can be used on adjustable beds, and roll-packed without causing any harmful stress to the unit.

TRUE-FLEX // 6 gauge spring steel border rod enhances edge support and resiliency.

SEMI-FLEX // The unique grid/leg assembly is very efficient, firmer, durable and noiseless. Reinforced grid adds surface coverage and enhanced stability. The performance grid is 14% stronger than the original 3 gauge border. A complete one piece steel foundation with no separate components. Passes all durability tests including Cornell, Rollator, and Impact.

CALIBER EDGE // Pocketed coils with a different diameter gauges that allow strength and stability around the perimeter of the mattress.

INNERSPRINGS // All our innerspring mattresses are manufactured using recycled domestic steel. We do not use any imports. Most of our premium line use a 13-gauge (heavy duty) innersprings. Our 660 coil (full size) features inverted innersprings and the helical coil is run lengthwise. This also helps reduce motion transfer.

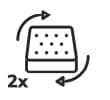

FOUNDATIONS // Heartland is committed to a quality box spring. Most mattress sags come from lesser quality bed frames or no center support and box spring failure. As a sales rep, this must be stressed. We require all bed frames to have a minimum of one center support leg to the floor (king size needs four).

QUALITY WORKMANSHIP // While we do not claim to build a perfect mattress, we strive to come as close as humanly possible. Each individual mattress is handcrafted and inspected prior to shipment. Heartland Mattress LLC is dedicated to maintaining a standard of excellence in quality and workmanship with a goal to build a brand name (Heartland) that you can trust for generations.

What is Foam?

IFD TEST (IDENTIFICATION FORCE DEFLECTION)

This test (formerly termed ILD, or Indentation Load Deflection) is one of the most important for almost all foam applications. The test itself is a simple one. A fifty square inch disk compresses a standard size piece of foam (15″x15″x4″ high). The foam is gradually compressed to 3″ high (losing 25% of its original 4″), then down to 1.22″ (losing 65% of its original height). Force readings (in lbs per fifty square inches) are taken at both points.

DENSITY & FIRMNESS

In interpreting the results of IFD testing, we must remember the relationship between density and firmness in polyurethane foam. Density is weight per cubic foot, while IFD measures the firmness which results from a combination of the particular chemical formulation and the density (which is actually the weight of the chemicals used in the foam). A low rating at 25% IFD means a small amount of pressure produces a significant indentation – the foam is soft to the touch.

If you want a foam with surface softness but with firmness at greater depth, you’re looking for a foam with a low 25% IFD rating and a high 65% rating – a form that initially compresses easily, but fights back more at greater compressions because of greater density. The degree of firmness at different compressions is affected by density and the particular chemical formulation. A medium density foam can be made extremely firm through chemical formulation. Similarly, a high density foam (3½ lb/sq. ft.) can be manufactured to yield considerable softness. The point is this: density describes the weight of the foam, while IFD ratings show how supportively the foam will function at different degrees of compression.

![Carlston Amish Bedroom Set [Sap Cherry with a Mineral finish]](https://amishdirectfurniture.com/wp-content/uploads/2022/07/Carlston-Mineral-340x340.jpg)

![Malaya Amish Collection [Chair, Sofa, and Coffee Table]](https://amishdirectfurniture.com/wp-content/uploads/2022/09/Malaya-Setting-IDB-150x150.jpg)

![Amish Craftsman Electric Adjustable Writer's Desk with Pencil Drawer & Finished Backside [FVD-2654-CM-SS]](https://amishdirectfurniture.com/wp-content/uploads/2022/11/FVD-2654-CM-SS_model.jpg)

![Flush Mission Amish Bed [Brown Maple with an Almond stain, Amish Direct Furniture]](https://amishdirectfurniture.com/wp-content/uploads/2014/06/Flush-Mission-Queen-Bed-Brown-Maple-FC-42000-Almond.jpg)

![Amish Old Classic Sleigh Bed [Quarter Sawn White Oak with a Michael's Cherry finish]](https://amishdirectfurniture.com/wp-content/uploads/2014/06/ITO-023-old-classic-658x800.jpg)

![Amish Abby Bed [ITAB-032]](https://amishdirectfurniture.com/wp-content/uploads/2025/06/itab-032-abby-150x150.jpg)

![Amish American Mission Bed [ITAM-065]](https://amishdirectfurniture.com/wp-content/uploads/2025/06/Indian-Trail-ITAM-065-American-Mission-150x150.jpg)

![Amish Bailey Dining Chair [Side Chair]](https://amishdirectfurniture.com/wp-content/uploads/2021/05/Bailey-Side-Chair-150x150.jpg)

Reviews

Clear filtersThere are no reviews yet.